- Customer Stories

- /

- Drone-Based Corrosion Monitoring and Analysis System

Drone-Based Corrosion Monitoring and Analysis System

Automated detection of surface rust and coating failures using computer vision and drone data.

Detection accuracy for rust vs. non-rust surfaces

Reduced manual inspection cost

Coverage of hard-to-reach areas via drone automation

Trained on a diverse, real-world dataset, the models were optimized for deployment on autonomous drones and seamlessly integrated into the client’s digital twin platform for real-time, remote inspections.

Energy

Industry

USA

Location

Computer Vision, Machine Learning, Model Development, Data Labeling, MLOps & API Deployment, AI Integration with Digital Twin Systems

Services

$400,000+

Budget

Client required a fully automated solution capable of detecting corrosion on offshore structures, identifying coating failures, weld lines, and structural edges, and assessing the severity of degradation.

See what we can do for youSolution

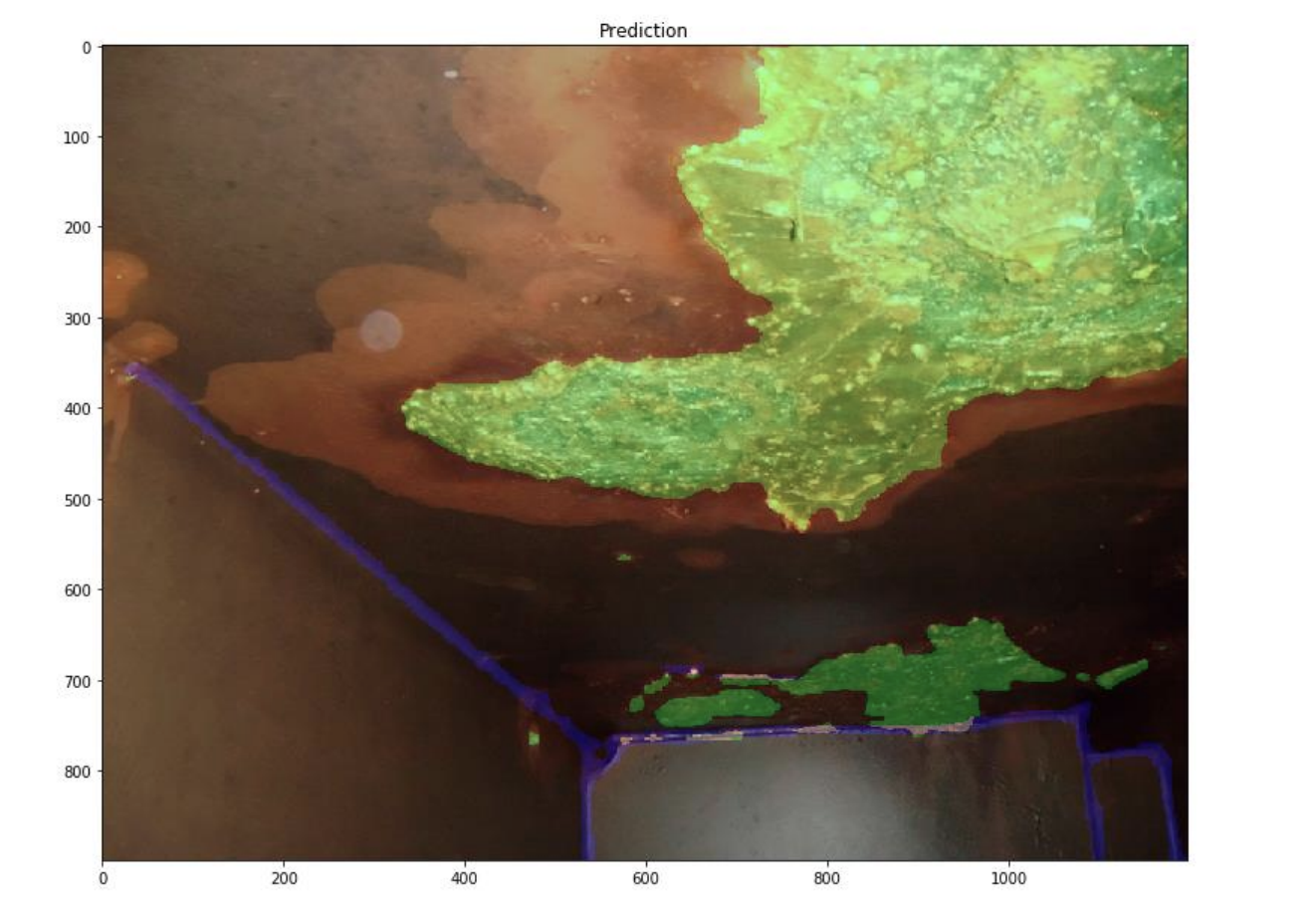

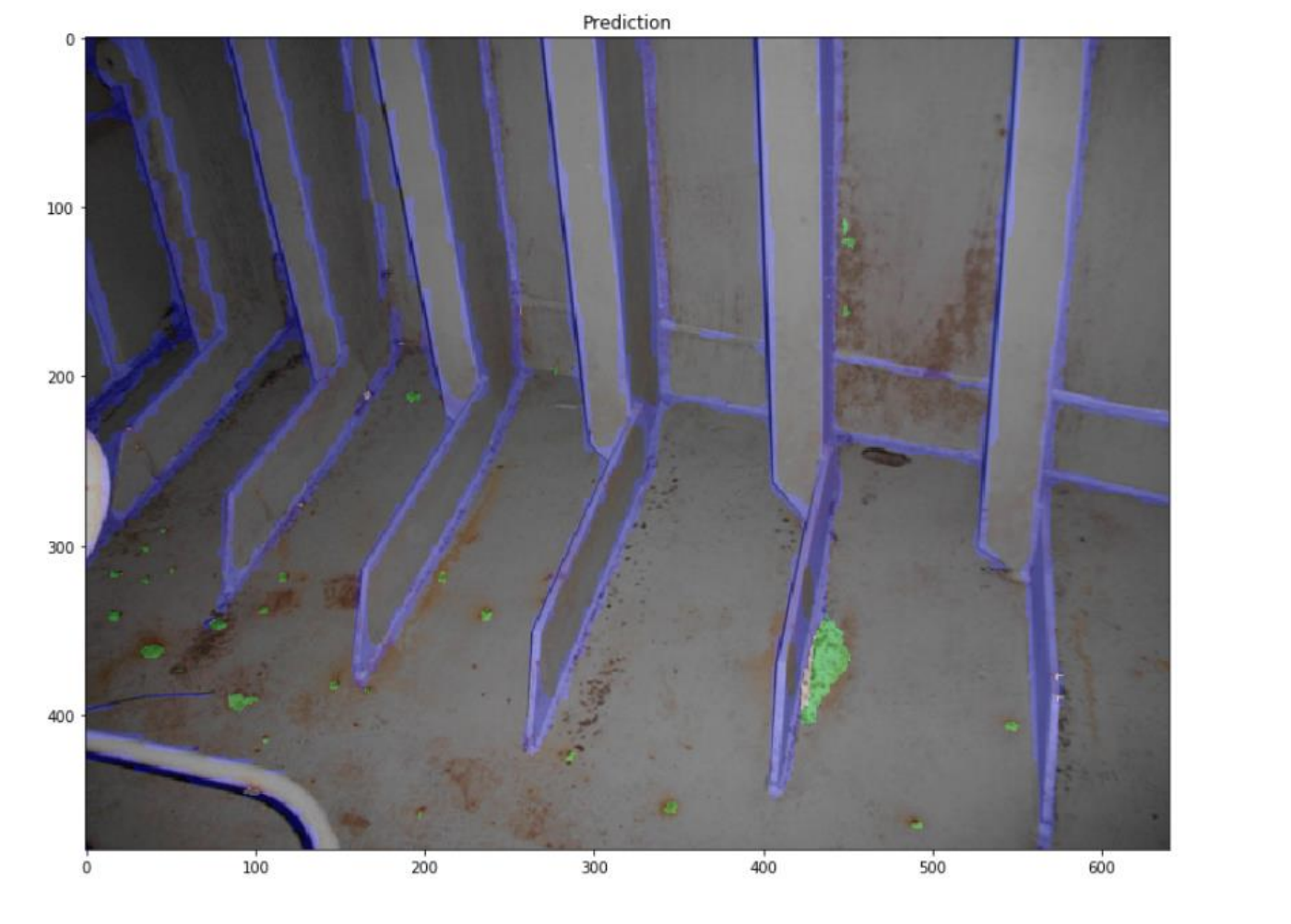

We developed a high-precision computer vision system that automatically classifies surfaces as corroded or non-corroded, segments coating breakdowns and evaluates rust severity in real time, and accurately detects weld lines and structural edges.

To develop computer vision system that automatically classifies surfaces as corroded or non-corroded, Blackthorn AI applied a production-grade tech stack including:

Project duration

Team Size

Delivering Impact

Beyond the values already highlighted, there’s even more to discover. Our commitment to innovation, client success, and impactful results sets us apart

Book a Meeting99%

Detection accuracyFor rust vs. non-rust surface classification, enabling precise corrosion identification across diverse surface types and environmental conditions.

88.9%

Linear IoUIn segmenting weld lines, coating boundaries, and structural edges—critical for assessing integrity in offshore assets.

100%

Visual coverageOf previously inaccessible or hazardous areas (e.g., underwater joints, pipe intersections) through autonomous drone integration.

60%

Reduced manual inspection costsBy eliminating the need for on-site personnel, scaffolding, and vessel-based access.