- Customer Stories

- /

- Industrial Computer Vision Quality Control System

Industrial Computer Vision Quality Control System

Stabilizing quality control after a production and lighting redesign in automotive manufacturing

Reduction of pseudo-errors after lighting and process change

Stable heating wire position verification tolerance

Automated OK / NOK decision with machine blocking

After a full redesign of the production line – including new lighting conditions and updated tooling – Gentherm’s existing computer vision system began producing a high volume of false positives during inspection.

Cross – Industry

Industry

United States

Location

$200,000–$500,000

Budget

CI/CD deployment, Warehouse design, Web portal

Services

The algorithm could no longer reliably detect whether the heating wire was positioned within the allowed ±1.5 mm tolerance relative to the product contour. As a result, the system frequently blocked the machine despite correct placement, slowing down the line and reducing overall equipment efficiency (OEE).

See what we can do for youSolution

Blackthorn AI developed a fault-tolerant large-scale genome analysis platform capable of handling hundreds of terabytes of raw sequencing data.

To deliver a a fault-tolerant large-scale genome analysis platform, Blackthorn AI applied:

Project duration

01 Week

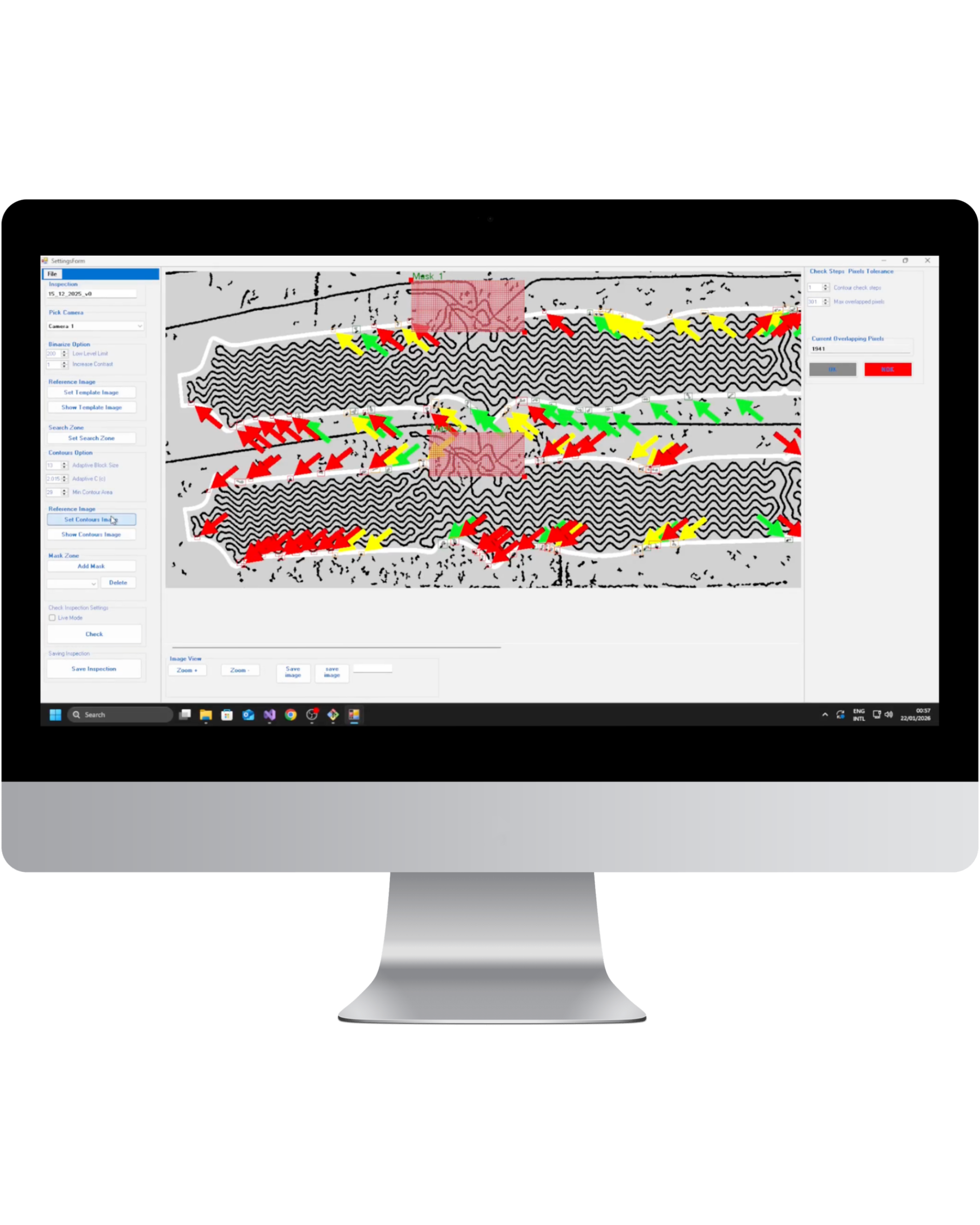

Analyzed the existing computer vision system after production and lighting redesign. Identified root causes of false positives related to illumination changes, contrast loss, and contour instability across multiple templates.

02-03 Weeks

Reworked image preprocessing and contour detection logic to ensure stable heating wire recognition under new lighting and material conditions. Improved robustness without changing inspection tolerances or production cycle time.

03-04 Weeks

Validated wire-to-contour positioning against predefined geometric tolerances (±1.5 mm). Ensured consistent behavior across all production templates and seat configurations.

05 Week

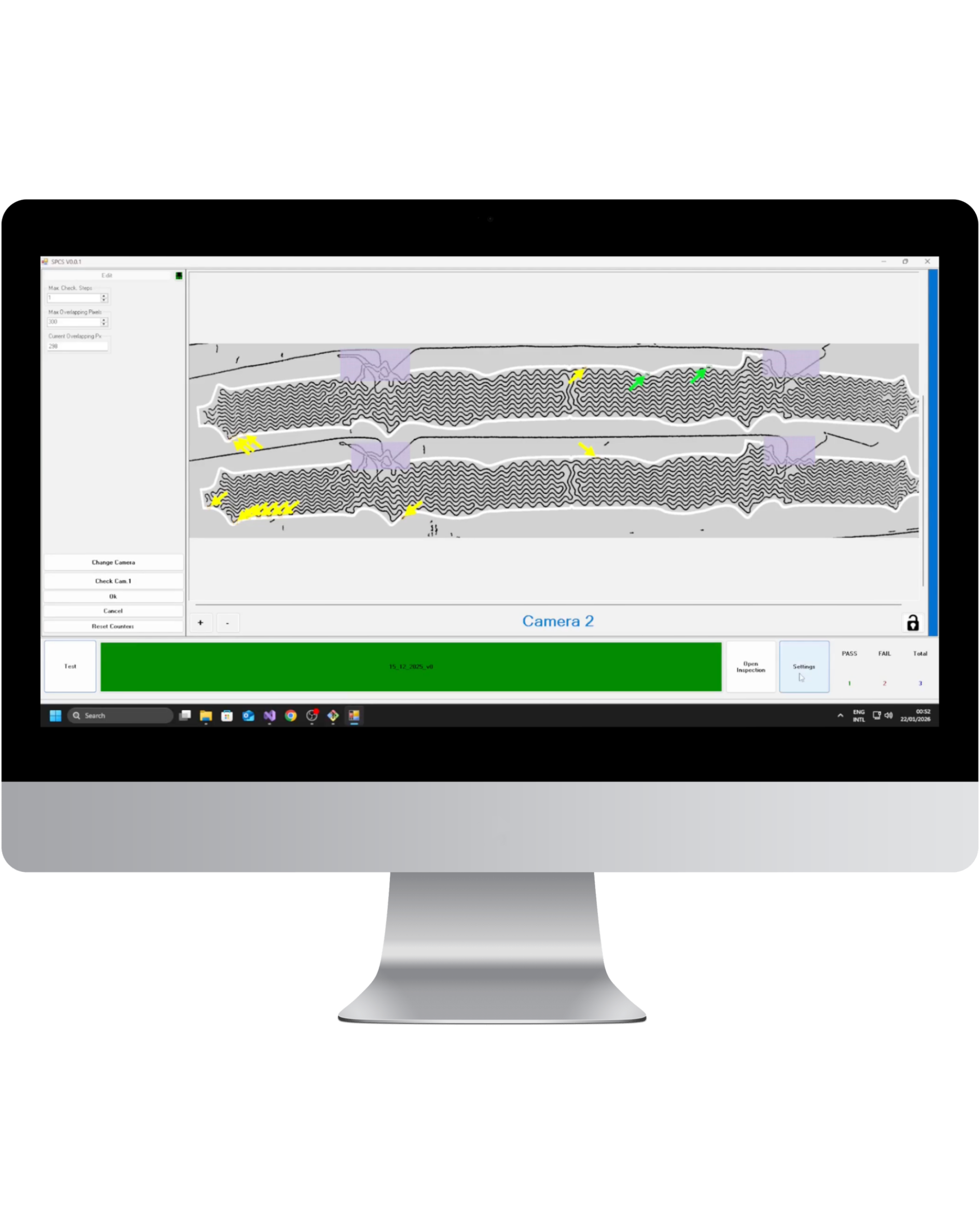

Deployed the updated algorithm to the production environment. Ran joint validation with Gentherm’s team to confirm reduction of false positives and stable real-time operation during live manufacturing.

06 Week

Implemented minor adjustments based on production feedback. Finalized the solution as a white-label update, fully integrated into the existing inspection system.

Team Size

Delivering Impact

Beyond the values already highlighted, there’s even more to discover. Our commitment to innovation, client success, and impactful results sets us apart.

Book a Meeting~1

SecReduction of pseudo-errors after lighting and process change

~1.5

MmStable heating wire position verification tolerance

100%

AutomatedOK / NOK decision with machine blocking