Energy

Corrosion Detection

The project was delivered for a multinational oil & gas corporation ranked as one of the top publicly traded companies by market capitalization.

Business Goals

- Detect the corrosion, identify the surface covered with rust, and its severity.

- Automate inspection of oil platforms.

Challenge

- Marine and offshore structures maintenance are costly due to the involvement of expensive personnel and the need to deliver them to the facility. Besides, the losses include stopping the oil production for the inspection period. The venue was supposed to produce nearly 130 thousand barrels of crude oil during this time!

- Some surfaces are physically unavailable for a human inspection, for example, pipes over the ocean or hard-to-reach places inside the platform.

Results

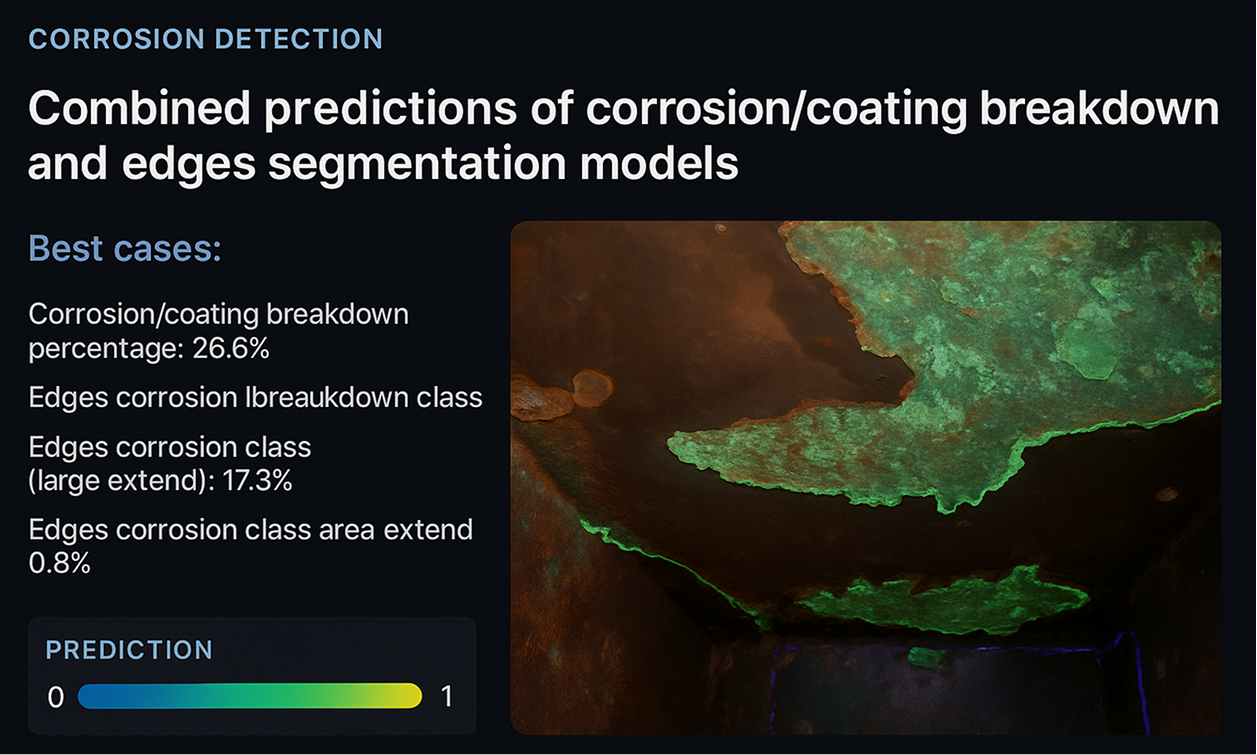

- The solution demonstrated 100% accuracy in near real-time rust detection (classification into `contains rust` and `doesn’t contain rust` categories) and 0.67 Intersection-over-Union (IoU) for segmentation of corroded regions.

- The solution was integrated as a module of an oil platform digital twin, allowing real-time facility assessment and access to hard-to-reach locations.

Implementation Details

- First, the data strategy was designed, and appropriate data were collected and labeled.

- Then, the images were classified into containing rust and not containing rust.

- Lastly, a number of state-of-the-art segmentation models (UNet, FCN, PSPNet, etc.) with various backbones (ResNet, Inception, EfficientNet, etc.) were trained, validated, and the best model was chosen.

Get a technical consultation

Alex Gurbych

Chief Solutions Architect

Receive a professional and in-depth consultation from an experienced expert. Get tailored advice to address your specific needs and achieve your goals effectively.